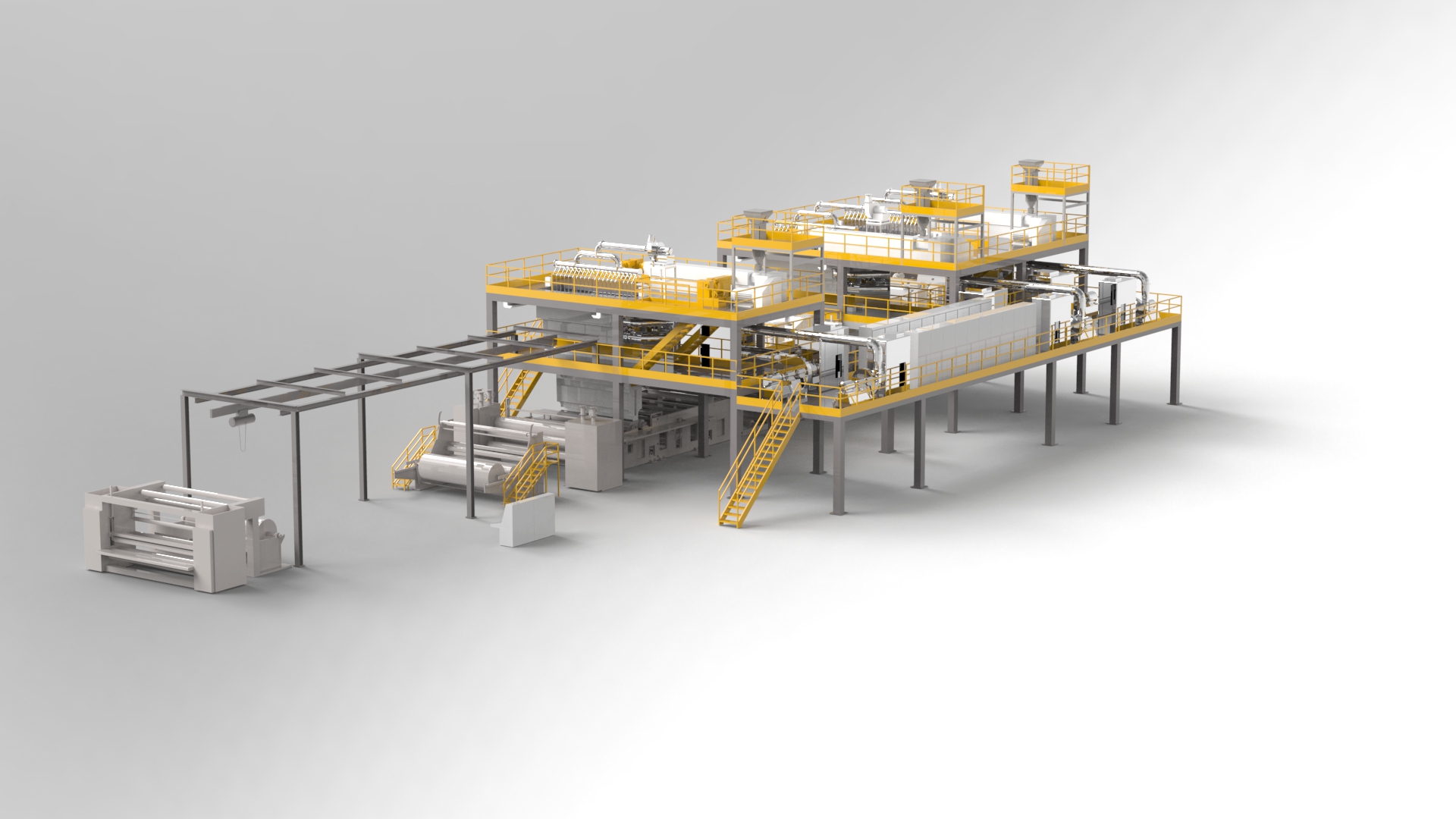

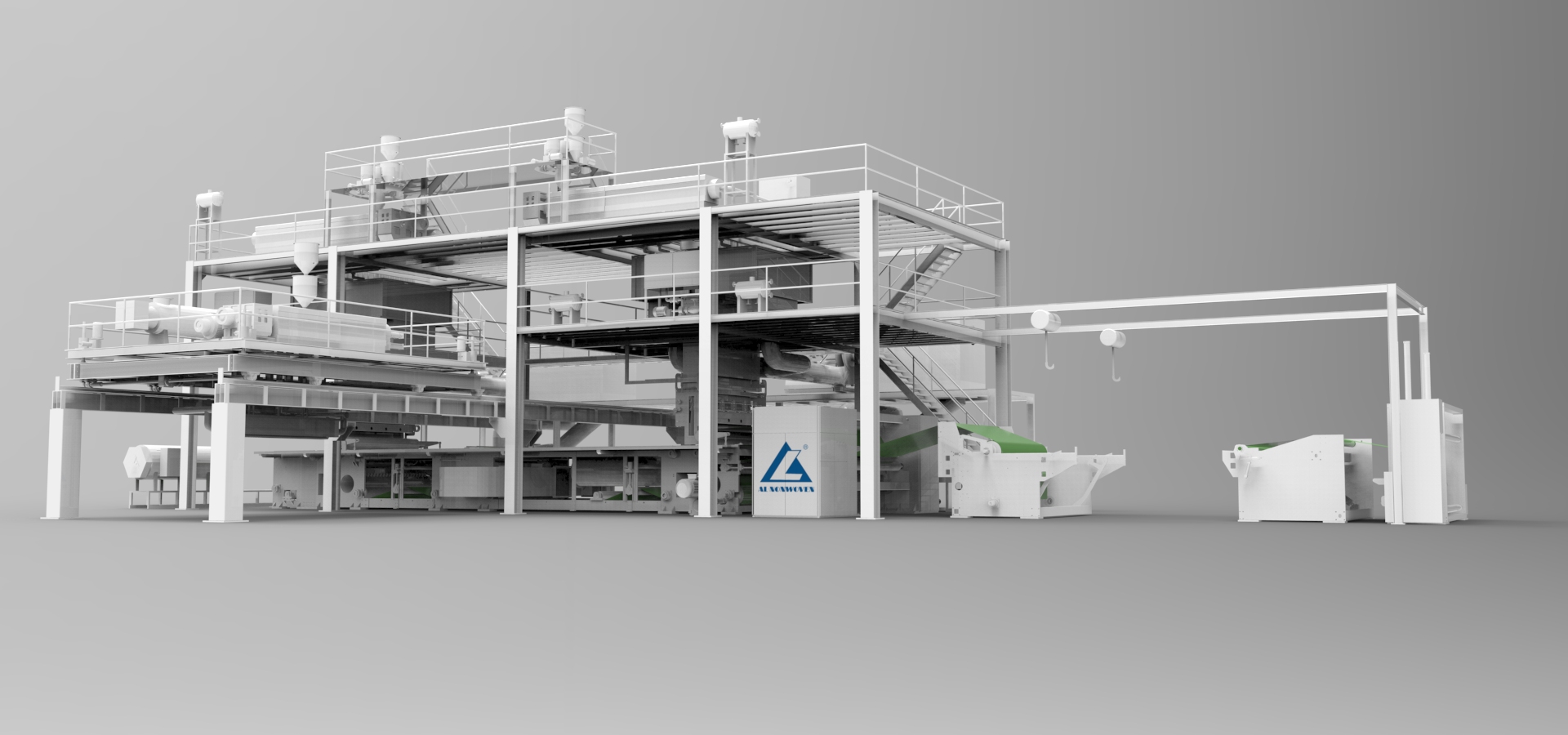

SMS nonwoven fabric making machine is a specialized industrial apparatus used to create nonwoven fabrics by combining spunbond and meltblown processes into a single, layered material known for its strength and filtration efficiency. SMS stands for Spunbond-Meltblown-Spunbond. This machine has become a cornerstone of various industries including healthcare, hygiene, and agriculture due to its ability to produce multi-layered fabrics with distinct properties tailored for specific applications.

Technical Specifications

SMS nonwoven fabric machine offered by A.L Nonwoven can produce SMS nonwoven fabrics that are not only strong but also offer excellent filtration properties.

Working Width

(mm)

1600

2400

3200

Speed

(m/min)

≤350

≤350

≤350

Machine Size

(L*W*H, m)

36*24*12

36*25*12

36*25*12

Fabric Gram

(g/㎡)

10-150

10-150

10-150

Daily Capacity

(Tons/Day)

11

16

21

Annual Output

(Tons/Year)

3500

5000

6500

Power

(Kw/h)

800

1200

1600

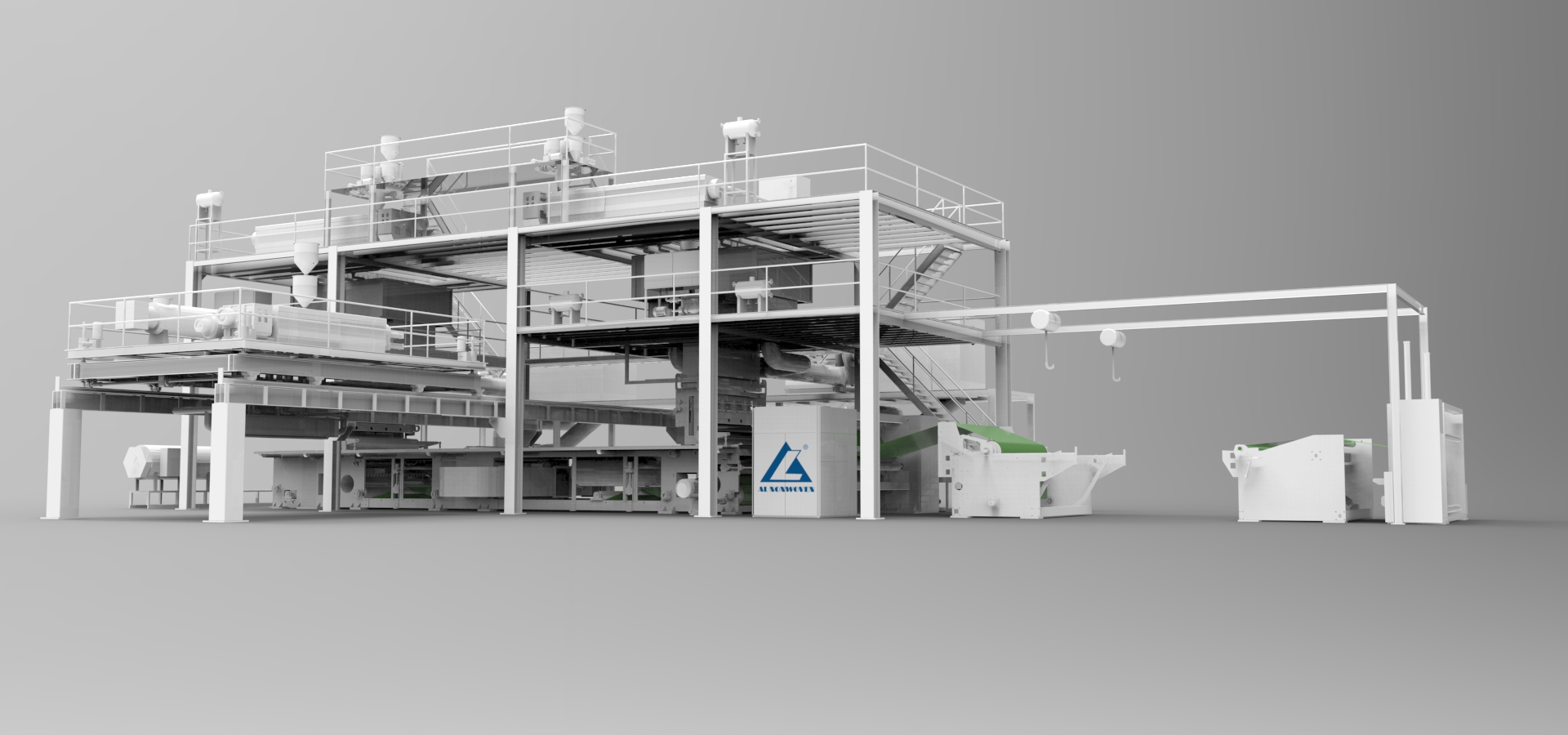

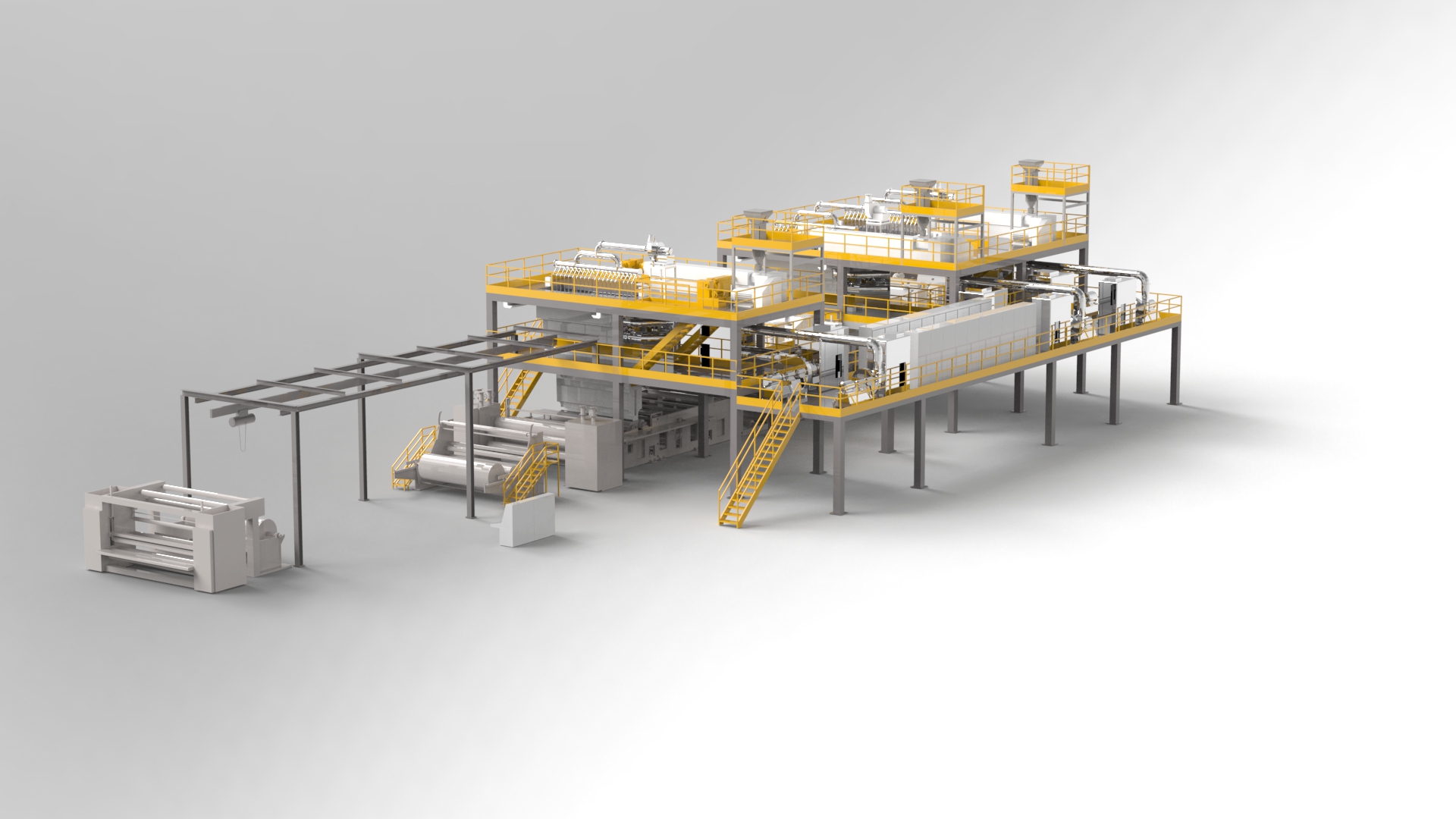

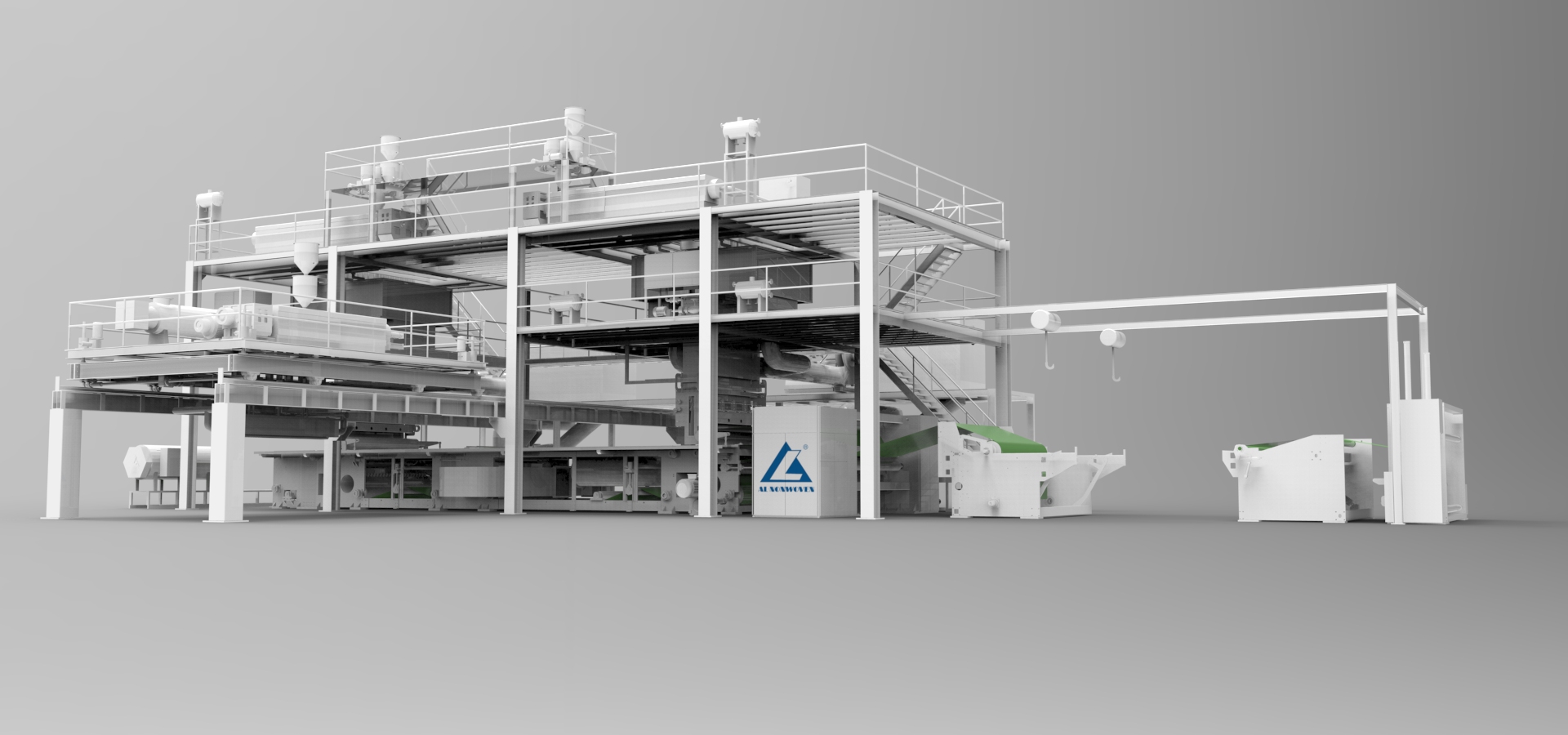

SMS Nonwoven Machine Series

A.L Nonwoven has experienced engineers and service team to develop and install our SMS nonwoven machines from 1600mm

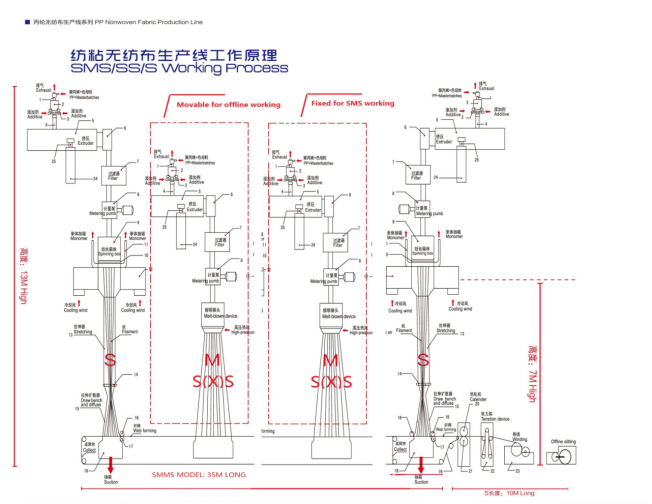

SMS Nonwoven Fabric Production Line Flow Chart

What is SMS Nonwoven Fabric?

Benefits of SMS Non Woven Fabrics

High Durability

Higher durability and rigidity compared to other types of non-woven fabrics. This makes it widely used in medical applications and the production of household products.

High Filtering Ability

Better filtering ability compared to other types of non-woven fabrics. Therefore, it is widely used in the production of filtration products such as masks, air filters, and water filters.

Waterproof Ability

Better waterproof ability compared to other types of non-woven fabrics, used in the production of waterproof products such as raincoats, waterproof bags, and liners.

You Might Also Want to Know

-

How to Choose PP Spunbond Nonwoven Fabric Making Machine?

Are you in the market for a PP spunbond nonwoven fabric making machine? With the increasing demand for nonwoven fabrics in various industries, it is essential to choose the right machine that can efficiently produce high-quality products.

-

How to Maintain Nonwoven Fabric to Ensure The Best Filtration Efficiency

In today's industries, the demand for effective filtration has never been higher. Nonwoven fabrics are often at the heart of advanced filtration systems due to their versatility and effectiveness. This article aims to enlighten readers on the essentials of maintaining nonwoven fabric to ensure it de

-

Can Nonwoven Fabrics Be Machine-Washed for Cleaning?

Nonwoven fabrics have become increasingly popular in various applications ranging from medical to industrial uses. As these materials gain traction, the question arises: Can nonwoven fabrics be machine-washed for cleaning? Understanding the properties of nonwoven fabrics and their washing requiremen

-

SMS Nonwoven Machine Production Process

SMS nonwoven machine production process is a crucial aspect of the textile industry. This innovative manufacturing process plays a significant role in producing SMS nonwoven materials, which have gained immense popularity due to their versatile applications and numerous benefits.

FAQs

- Q: Is SMS Material Waterproof?A: SMS material is not inherently waterproof. It is a nonwoven fabric that allows air to pass through, which is why it is used in applications like masks and medical gowns. However, SMS fabric can be treated with a hydrophobic agent to make it water-resistant. This treatment modifies the surface of the fabric to repel water, but it does not change the fabric's basic structure or its breathability properties.

- Q: What Is SMS Nonwoven Fabric?A: SMS Nonwoven Fabric, also known as Spunbond-Meltblown-Spunbond, is a type of nonwoven material that is engineered with three layers. The outer layers are made from Spunbond polypropylene, which provides strength and durability, while the middle layer is composed of Meltblown polypropylene, offering excellent filtration properties. This tri-laminate structure makes SMS fabric ideal for applications requiring both strength and filtration, such as medical gowns, masks, and filters.

- Q: What Is The Difference Between SMS And Spunbond?A: Spunbond is a single layer of nonwoven fabric made from continuous filaments that are bonded together. It is known for its strength and durability. In contrast, SMS is a composite fabric with three layers: two outer Spunbond layers and one inner Meltblown layer. The Meltblown layer in SMS enhances the fabric's filtration capabilities, making it suitable for more specialized applications compared to standard Spunbond.

- Q: What Are The 3 Main Types Of Nonwoven Fabric?A:

- Spunbond - A nonwoven fabric made from continuous filaments that are bonded together, known for its strength and durability.

- Meltblown - A nonwoven fabric produced by melting the polymer and then blowing it through small orifices to form fine fibers, which are then bonded together. It is known for its high filtration efficiency and softness.

- Spunlace - A nonwoven fabric created by using high-pressure water jets to entangle fibers, which are then bonded together without the need for heat or adhesives. It has a soft texture and is often used in personal care products.

- Q: What Are The Two Major Types Of Making Nonwoven Fabric?A:

- Mechanical Bonding - This involves using mechanical means such as needle punching or hydroentangling to interlock fibers and create a fabric.

- Chemical Bonding - This process uses adhesives or chemical agents to bond fibers together. The fibers can be webbed together in various patterns to create the desired fabric properties.

- Q: What Is The Difference Between SMS And SMMS Fabric?A: The additional Meltblown layer in SMMS fabric enhances the filtration capabilities and barrier properties compared to SMS. SMMS is often used in applications requiring higher levels of filtration and protection, such as high-efficiency masks and protective clothing.

What Kind of Products Would You Want To Produce

Nonwoven fabrics have revolutionized various industries with their remarkable versatility and functionality. If you know what you want to produce but are unsure which type of nonwoven machine you need, please feel free to contact us. We will be happy to guide you to the right machine or production line.

Medical

Providing fabrics that securely safeguard the well-being of healthcare workers and patients alike.

Hygiene

Providing fabrics that greatly enhance our health and living standards.

Industrial

Providing fabrics that support the smooth operation of industrial advancements and logistics processes.

Agricultural

Providing fabrics that safeguard crops and guarantee good yield.

Consumer Products

Providing fabrics that maintain the freshness of food, shield it from contamination, and facilitate the secure transportation.

Keep in touch with us

Mob:+86-137-0679-6923

E-mail:angel@alnonwoven.com