SSS nonwoven fabric making machines is a specialized piece of equipment that creates nonwoven fabrics using multiple layers of spunbond technology, characterized by their high strength, uniformity, and versatility. These machines are primarily employed to produce fabrics used in a multitude of applications, including medical supplies, personal hygiene products, and agricultural coverings.

At its core, the SSS type machine employs the spunbond process, which involves extruding melted polymer consistently through spinnerets to form continuous filaments. These filaments are laid down simultaneously to create a robust network of fibers. The "SSS" designation indicates that the machine utilizes three layers of spunbond, substantially enhancing the strength and durability of the fabric produced.

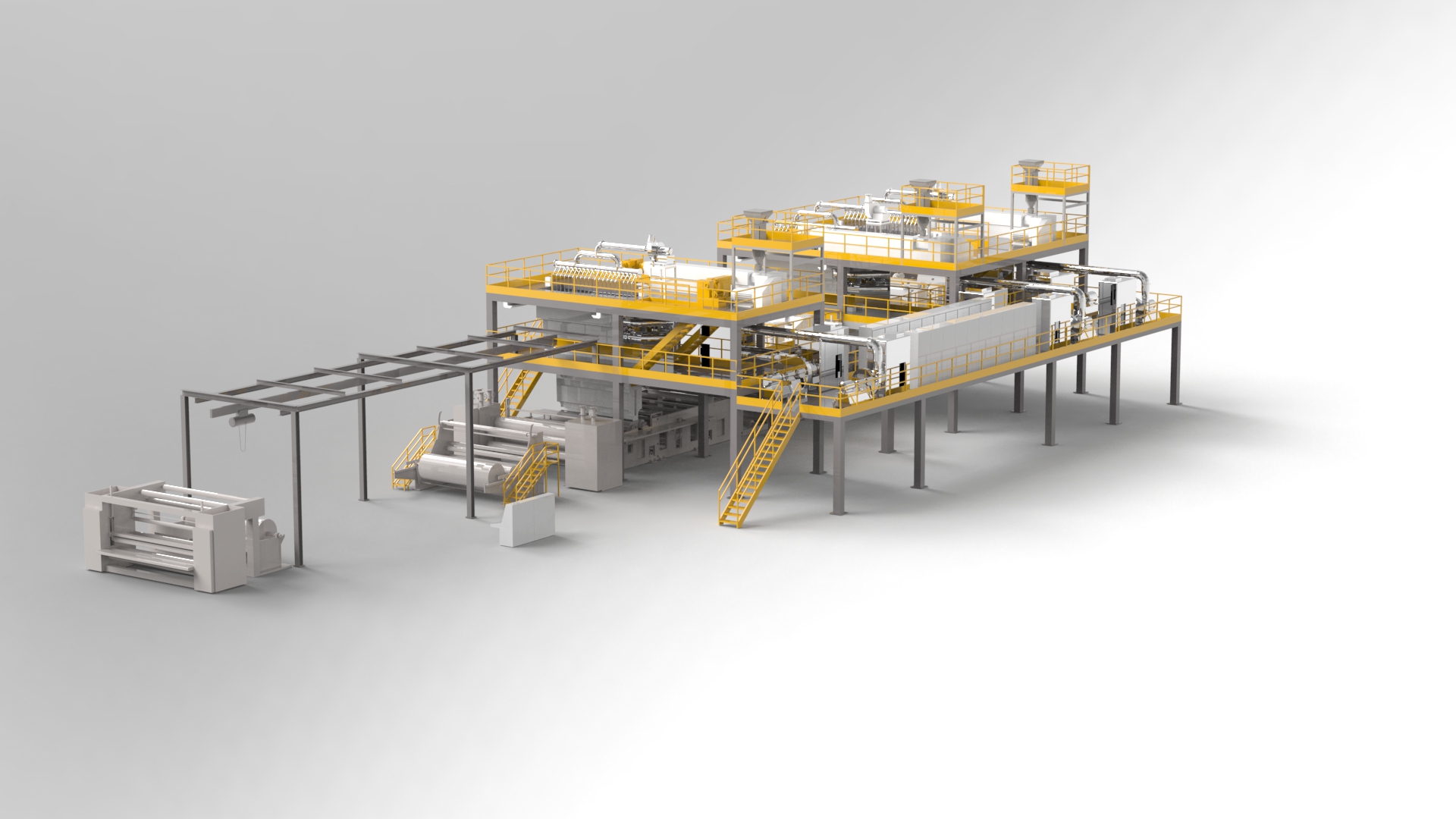

SSS Nonwoven Fabric Production Line Technical Specifications

SSS nonwoven fabric production lines offered by A.L Nonwoven have automated and refined the nonwoven fabric production process, enhancing both the quality of fabrics produced and the efficiency of manufacturing operations.

Working Width

(mm)

1600

2400

3200

4200

Speed

(m/min)

≤300

≤300

≤300

≤300

Machine Size

(L*W*H, m)

36*12*12

36*13*12

36*13*12

36*14*12

Fabric Gram

(g/㎡)

10-150

10-150

10-150

10-150

Daily Capacity

(Tons/Day)

12

18

25

27

Power

(Kw/h)

300

400

600

750

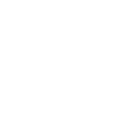

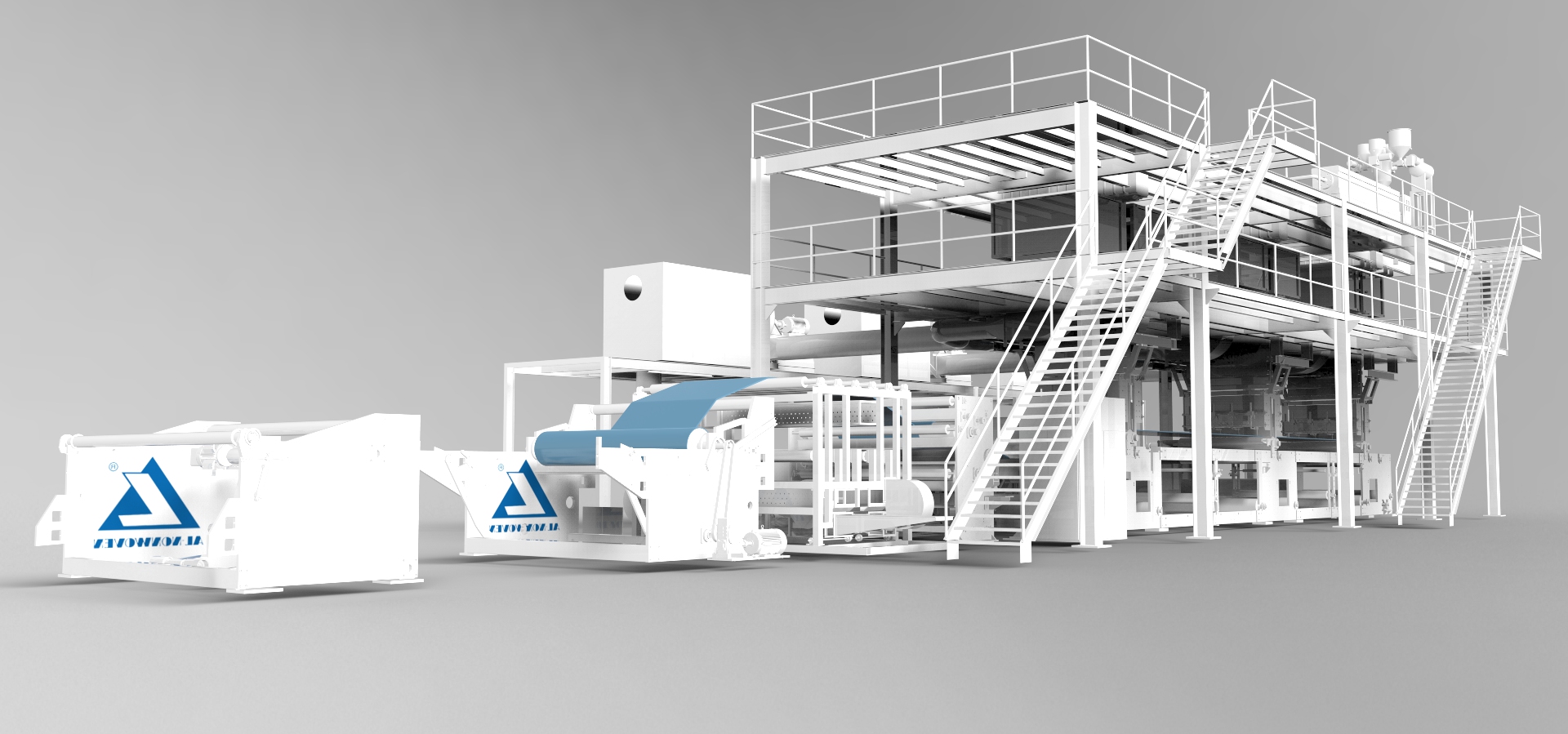

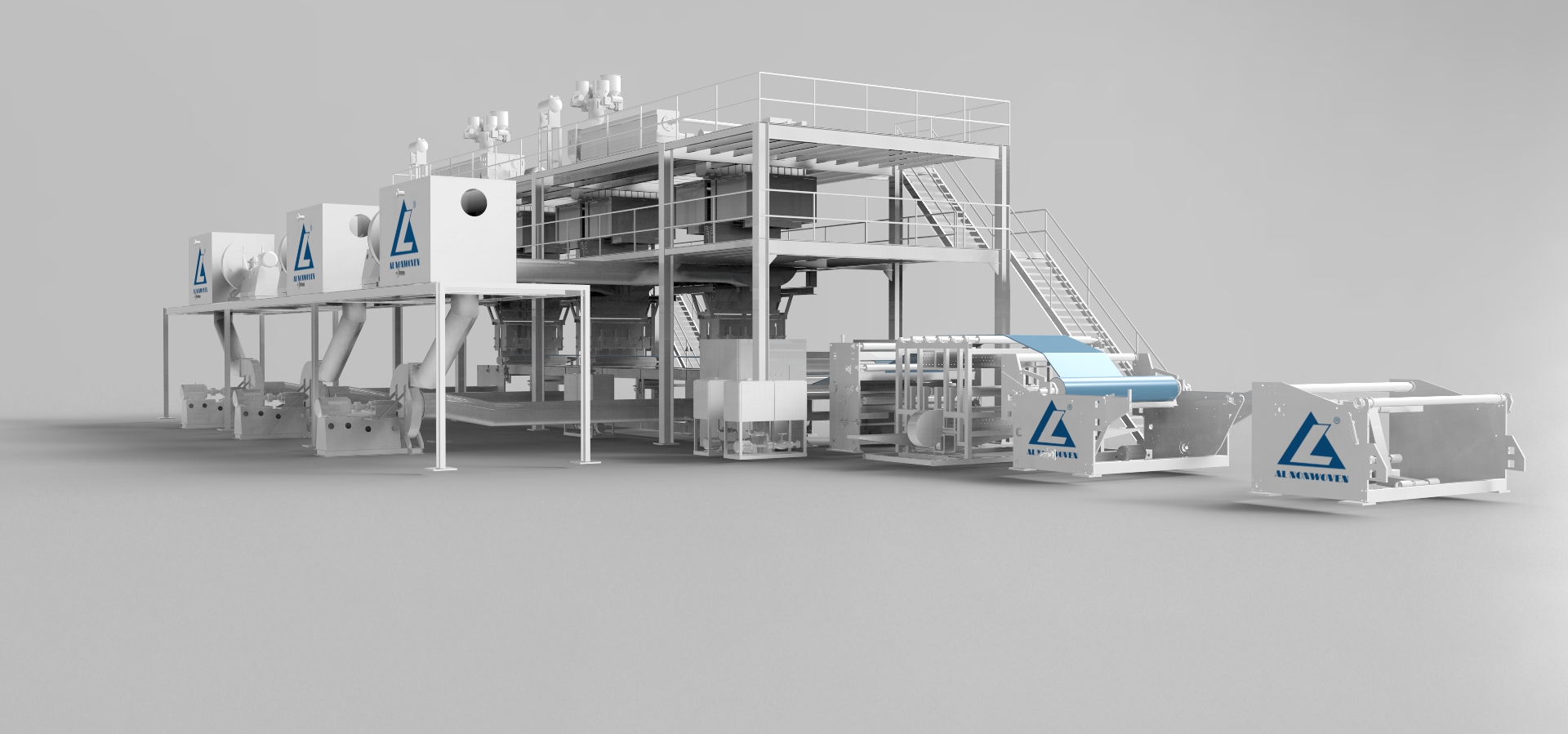

SSS Nonwoven Machine Collection

A.L Nonwoven provides comprehensive pre and after sales services for SSS nonwoven machine, including sample testing, on-site factory visits, free spare parts and more.

SSS Spunbond Nonwoven Line

Working Process

The production process of SSS nonwoven fabrics encompasses several stages: PP chips ---> pneumatic conveying ---> extruder melting ---> filtering ---> spinning ---> stretching ---> web forming ---> calendar bonding ---> winding ---> offline slitting. The polymer, usually polypropylene, is first melted and then extruded through spinnerets to create continuous filaments. These filaments are then stretched and cooled before being laid down to form a web. This web formation process is meticulously controlled to ensure uniform distribution of fibers.

Lastly, the web of fibers is bonded through thermal or chemical processes to create the final fabric. This bonding stage is crucial as it determines the fabric's strength, uniformity, and other properties.

Advantages of SSS Nonwoven Fabrics

Durability and Strength

One of the primary advantages of SSS nonwoven fabrics is their exceptional durability and strength. Unlike traditional woven materials, SSS nonwovens are produced by bonding long fibers together through a melt-blowing technique. This method results in a fabric that is not only strong but also resistant to wear and tear. The multiple layers in SSS materials provide added strength, making them ideal for applications requiring robust and reliable materials. For example, in the medical field, SSS nonwoven fabrics are used to make surgical gowns and drapes that must withstand rigorous use without tearing or fraying.

Breathability and Comfort

Another critical advantage of SSS nonwoven fabrics is their breathability. The unique structure of these fabrics allows air to pass through while blocking moisture and particulates. This quality makes them perfect for applications where ventilation is crucial. In healthcare, for instance, the breathability of SSS nonwovens ensures that surgical masks and gowns are comfortable for prolonged wear, reducing the risk of overheating and sweat accumulation. Additionally, this breathability makes SSS fabrics ideal for disposable diapers, providing comfort to infants by allowing their skin to breathe and stay dry.

You Might Also Want to Know

-

How to Choose PP Spunbond Nonwoven Fabric Making Machine?

Are you in the market for a PP spunbond nonwoven fabric making machine? With the increasing demand for nonwoven fabrics in various industries, it is essential to choose the right machine that can efficiently produce high-quality products.

-

Understanding the PP Spunbond Non-Woven Fabric Manufacturing Process

The demand for non-woven fabrics has surged in various industries, from healthcare to agriculture, due to their versatile applications and cost-effectiveness. Among the different types of non-woven fabrics, PP spunbond non-woven fabrics have gained significant traction because of their strength, dur

-

Manufacturing Process of Spunbond Nonwoven Fabrics

In the realm of textile engineering, the innovation of spunbond nonwoven fabrics has marked a significant leap forward in material science. Originating from the ingenious use of spunbond machines, these fabrics are crafted through the extrusion and stretching of polymers, resulting in the formation

-

How to Maintain Nonwoven Fabric to Ensure The Best Filtration Efficiency

In today's industries, the demand for effective filtration has never been higher. Nonwoven fabrics are often at the heart of advanced filtration systems due to their versatility and effectiveness. This article aims to enlighten readers on the essentials of maintaining nonwoven fabric to ensure it de

FAQ

The SSS process involves creating multiple layers of spunbond fabric, enhancing the strength and durability compared to single-layer processes.

What Kind of Products Would You Want To Produce

Nonwoven fabrics have revolutionized various industries with their remarkable versatility and functionality. If you know what you want to produce but are unsure which type of nonwoven machine you need, please feel free to contact us. We will be happy to guide you to the right machine or production line.

Medical

Providing fabrics that securely safeguard the well-being of healthcare workers and patients alike.

Hygiene

Providing fabrics that greatly enhance our health and living standards.

Industrial

Providing fabrics that support the smooth operation of industrial advancements and logistics processes.

Agricultural

Providing fabrics that safeguard crops and guarantee good yield.

Consumer Products

Providing fabrics that maintain the freshness of food, shield it from contamination, and facilitate the secure transportation.

Keep in touch with us

Mob:+86-137-0679-6923

E-mail:angel@alnonwoven.com